Rights Reserved - Free Access.

This digital object is protected by copyright and/or related rights. This digital object is accessible without charge, but its use is subject to written permission.

Unless expressly stated otherwise in the licensing conditions, you are free to make any of the acts permitted by your national copyright and related rights act, including browsing, printing and making a copy for your own personal purposes.

All other acts of reproduction and communication to the public are subject to the licensing conditions attached to the digital object.

ARMY BOOTS OF THE WORLD. REVIEWS

Important notice: we do not sell any boots! The prices are given for information purposes only!

Belgium ![]()

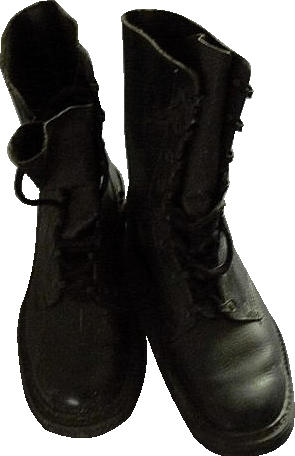

Belgian Military Boots (from late 1960s to mid-1990s)

Belgium today is a very small and cosy European country, but one shouldn't underestimate this nation. Belgium is not just and not only the Flemish lace, the Liège waffle and the chocolate of Brussels ... Since the founding of this country it was a small sharp-toothed predator, and back in the previous centuries it had huge overseas colonies.

By its level of development in the early 20th century this country was ahead of many other European countries and was deservedly among the leaders, especially for the production of steel. In contrast to the neighbouring Netherlands, during the First World War Belgium was quite affected by the combat activities. This was largely due to the fact that Germany was trying actively to weaken the potential industrially strong competitor. In those years in Africa, the Belgian Congo was a powerful source of raw materials for Belgium, as well as their other colonies: Burundi, Rwanda...

The stable position of Belgium as a major power was also provided by strong efficient army with a long military traditions. Nowadays many international organizations, primarily NATO has their headquarters in Brussels - this is just an echo of the glorious past of Belgium.

A division of the Belgian para-commandos (paratroopers commando) is one of the oldest in the world. The Belgian paratroopers enjoy well-deserved recognition of their foreign counterparts due to the high level of training, high mobility, operational readiness for the challenges anywhere in the world. The glorious history of these units began in England in 1942, when a company of Belgian volunteers were trained by the famous British "SAS" specialists. During the Second World War, the Belgian commandos took an active part in the Allied operations in North Africa, Italy, Yugoslavia, the Netherlands and Belgium itself. The red berets and insignia of the Special Air Service (SAS) proudly worn by modern paratroopers is still the reminiscent of that events. In the 1960-70s, the Belgian para-commandos have participated in the fighting and rescue operations of European settlers from African rebels. Even Germany, which at that time was deprived of the opportunity to have a similar unit was forced to seek the help of Belgian paratroopers to rescue their citizens.

The introduction of high-laced combat boots in the US Army began with paratroopers. They were the first to wear the "Corcoran"-type high-laced brown boots, which were designed in the year 1940 to protect the paratroopers against occupational injuries like ankle sprains and dislocations. For the paratroopers these boots were a subject of pride and envy of all the other branches of service. The contemporary marines wore low boots with gaiters, and even the "brothers" of regular paratroopers - the glider paratroopers, which had to land from air planes somewhere behind the enemy lines on silent non-motorized gliders, had to wear the same boots as the foot soldiers. Later, during the Korean War, all the other units of the US armed forces started to wear the high-lace boots.

As for the Belgian military of the 1940-1960s, the situation was similar. While paratroopers wore high boots, all other had to wear low boots (quite similar in construction and tread design) with canvas gaiters, which featured semicircular leather lining patches, sewn inside to protect the malleolus bones. By the late 1960s, already all the Belgian military staff wore the high-laced boots.

According to my personal customer feelings, the Belgian army boots are one of the most robust and user-friendly boots I have ever worn. Successful yet simple design, robust glued and stitched out-soles made of hard vulcanized rubber, durable but soft grain leather, easy lacing make these "ankle boots" very recognizable. The boot's tongues are stitched to the top on the level of seventh pair of eyelets (semi-closed flap) - this helps to protect the feet from ingress of water up to that level. The leather is thick, but very elastic, the grainy structure provides some cushioning to protect from minor injuries.

The out-sole tread "double Y"-pattern is also of a unique Belgian design, easily distinguishable from all the other patterns. It is often called "RUGAK" by the name of the developer and biggest mass producer of these boots at that time.

Although Belgian boots look a bit like the French "Rangers", only without buckles at the top, the Belgian "ankle boots" differ with their characteristic unique design, and in the recent years they have been the subject of copying.

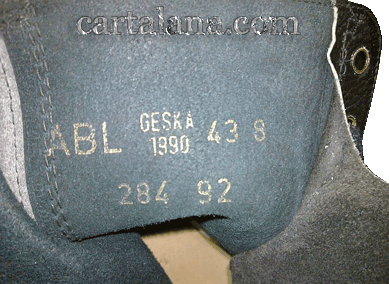

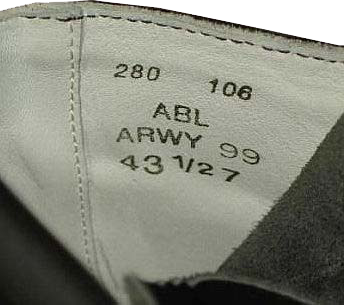

The main difference between the Belgian army boots from the similarly-looking boots of other countries is, of course, the marking. All the Belgian military boots (as well as the uniform and the other field equipment) are necessarily labelled "ABL" (Armèe Belge / Belgisch Lèger) which means "The armed forces of Belgium" in French (Walloon) and Dutch (Flemish).

The list of manufacturers Belgian army boots leather top:

"GESKA" ("Geska" NV) - the full name of this company was "A. Geyskens en Kinderen" from Testelt, and Rugak was sub company from Geska.

According to the information, kindly provided by Johan Geyskens (who belongs to the 4-th generation of Geyskens family), GESKA and RUGAK are the abbreviations:

RUGAK = RU (rubber)+ G (Geyskens) + A (Alfons) + K (kinderen = kids);

GESKA = GES (Geyskens) + K (kinderen) + A (Alfons)

Alfons was the name of the grandfather, Kinderen (Kids) = 4 boys and 1 girl were the border of the company.

During the discussion with the author of this review, Mr. Johan Geyskens emphasized, that real GESKA-RUGAK boots were NEVER produced anywhere besides Testelt (Belgium), and all the rumors about production in Portugal and other European countries are just speculation or mistakes.

Of course, there have been many attempts to arrange the production of the copies of GESKA-RUGAK boots... For example, such an attempt was made by a South-Korean footwear manufacturer, but no good result was achieved, so the production was stopped. The unbeaten quality boots can not be copied without "know-how" secrets....

If to compare two most wide-spread kinds of GESKA-RUGAK boots, the following peculiarities are worth mentioning:

- the left boot was made with the use of RUGAK old sole (with nails in heel), while the upper leather was thinner than usually (normally the upper leather had 2,0-2,2 mm of thickness). These boots and we made also for ABL Scouting troops.

- the right boot was made with new sole, and the heel was attached with 2-component glue. The newer boots were manufactured in the 1990-th, their out-soles had better grip with different surfaces and more modern look.

Both boots had been made in Testelt, Belgium, though the latest out-sole bears no "BELGIUM" inscription.

Depending on the boot's size, smaller-size boots have 8 pairs of simple round eyelets, like on the pictures below.

Medium and big sizes boots have 9 pairs of lacing eyelets,

There was a kind of ABL combat boots, which look like regular GESKA-RUGAK boots, but they have stitching on the sides.

This sewing line goes from the lower bottom side of the lacing eyelets, along the whole bootleg up to the boot's top. This stitching was intended to keep internal leather lining, under which there was foamed rubber (porolon), which acts as a padding to protect the side bones of the feet from injuries.

The same line can be seen on the Swiss KS 90 boots (KampfStiefel Modell 1990) and old Bundeswehr boots (Variant 3a: "Genarbtes Leder, Schnurung mit Haken (Grain leather, lace-through boots with hook clamps)), which had been produced from 1984 to 1993.

Mr. Johan Geyskens kindly informed the author of this review, that the production of this version of ABL RUGAK boots was started on demand from the Belgian Army command, because they saw the same feature in the aforementioned Bundeswehr boots. After some time these boots with side bones padding appeared to be not so good as it was supposed. The padding became the weak point of this model: after a while the lining used to come in bad condition, the socks began to wear off faster, and there were other problems with feet and the Achilles tendon, mainly because the feet could slide inside the boots while walking.

There was also a kind of GESKA-RUGAK safety boots, with steel caps, designed specially for such services as fire-fighters, construction engineers, maintenance and transport personnel, and those, working in garages etc.

In some cases such boots featured oil-resistant out-soles.

A kind of ABL GESKA-RUGAK boots with quick-lacing system have been produced for commando paratroopers as limited edition series and against the advice of GESKA-RUGAK, because quick lacing system is generally not so reliable and robust as simple round eyelets.

According to the GESKA opinion, in case if a quick-lacing system was broken down, the normal lacing process is impossible. More-over, quick-lacing system can be very dangerous for commando troopers during jumping out of plane. The cords of parachute can inter-mesh with the quick-lacing system rivets, that is definitely against safety requirements. So after a while GESKA-RUGAK stopped production of this ABL boots with quick-lacing system.

By GESKA-RUGAK experience, all the changes of the ABL boots concept used to arise with every next Minister of National Defense, who wanted to try something new, accept some ideas from the neighbor armies, and make some changes, but having no experience in this field. So after such attempts of integrating some novelties they had to return back to the original classic ABL model, because the experienced footwear manufacturers are much better experts and professionals in this field.

The famous "Geska-Rugak" ABL combat boots represented by themselves the advanced out-soles, created by the family’s technological secrets, and the "know-how" upper leather, which was created and implemented after many years of experience and field tests, performed by the family members themselves.

No wonder, that in the previous decades "GESKA" won every time the award for manufacturing the best combat boots of NATO countries."

- "ARWY NV" from Herentals, established on January 1, 1968, still exists today, taking third place in the industry.

The marking inside the boot generally consists of the manufacturer's name, as well as size and width of the boots in "Mondopoint" (in mm) and the European systems.

The out-soles of hard durable vulcanized rubber were produced by either:

- "SOLIDOR" ("Solidor Rubber & Products BVBA") from Lauva town in West Flanders. This is the first manufacturer of these boots (model 112). The out-soles with a classic "Vibram" pattern (lateral stripes on the welt and cross tabs, staggered in the middle of the sole and heel) of these boots show the logo - a walking little man in a circle, with inscription "SOLIDOR-BELGIUM" on the top and the bottom of the logo. This rubber production company exists today.

"Some Internet-sources (mostly forums) say, that "Geska" NV went bankrupt in the early 2000s, but this information is not true. "GESKA" stopped production in May 1997, because the taxes become too high and that was the reason that they closed the production line. Since this year the last of the old generation past away so the family sold all the machines to different footwear manufacturers, not only to Rubex.

Rubex was another footwear manufacturing company in Belgium, which worked together with "GESKA" to learn how to make the perfect "Rugak" out-soles. No doubt, neither company will produce such good combat boots again, because the secrets of Geska-Rugak boots manufacturing will stay in the family for ever."

- "RUBEX" ("RUBEX NV") was founded in 1959 in Moorsele. It was producing more soft and fast wearable out-soles. Since 2004, all the company's production was transferred to the town of Dolni Podluzi in Czech Republic, having left in Belgium only the headquarters and logistics centre.

Among the other manufacturers one should mention "FOSTEX" and different "copy-cats".

- "FOSTEX" is a Dutch company, founded in 1989, which now makes copies of classic Belgian military boots on China-based factories. Of course, only from the distance such copies are visually similar to the original Belgian boots.

By the level of production and the quality such boots are comparable to other replicas of the original army boots and other equipment: "Mil-Tec" (TSR = Thomas Sturm Rottenburg), "MFH" (Max Fuchs Hinterschmiding), "WRC" or "Roth Co." but falls far short of product quality to the level of contact suppliers, which follow the strict military standards. There are quite grotesque copies of Belgian boots from Chinese manufacturers which make and advertise their boots as "based on... " or made "...in the original Belgian-style". Such footwear looks similar to the originals only from far distance.

At the same time, one can still buy the original "RUGAK" ABL boots of the 1970-1990s, both new / used, which, indeed, fully maintain their excellent performance, still look great and are ready for use, for example, in the harshest conditions of multi-day hike.

The boots with "RUGAK" and "SOLIDOR" out-soles feature 9 pairs of lacing eyelets, while "RUBEX"-made boots - only 8 pairs.

In 1960-70 in Belgium, as well as in many other countries of the world, from Germany to South Africa, the sole was attached by glueing and stitching method. The out-sole tread pattern was shifted closer to the centre of the sole on the distance about an inch, and the resulting free space on the welt was stitched.

Later, due to the economy, this practice was cancelled in many countries, and the boots were used to be glued only, just as it was in the Bundeswehr footwear. But the Belgian boots were still stitched and glued, but without the tread pattern shift to the centre of the sole. In view of the thick and durable leather and rigidity of the rubber out-soles, the power of the broaching machines is simply amazing. The stitching was made through the very soles and the leather top.

Following the world-wide fashion, in the mid-1990s the Belgian armed forces began transition to the new model of the boots, the so-called "model 1996".

On the one hand, the novelty had obvious improvements, for example, there was a soft leather padding along the upper of the boot's top. The lacing system was changed as well: on top there were added five pairs of speed lacing eyelets on top, a pair of clamps for fixing laces below, and three pairs of simple round eyelets below.A cushioning and an additional layer of light-grey "glove"-type leather were added inside the boots and on the inner surface of the tongue, as it used to be in the previous "SOLIDOR" models of the 1970s and some more recent "ARWY"-made boots, though the old ones featured no soft paddings, serving just as an additional inner leather lining.

All these modifications made the new Belgian boots top virtually indistinguishable from the most recent Dutch boots of the model M90, so-called "Militaire Legerkisten M90 Landmacht Model".

However, there was clear deterioration as well - the out-sole was no longer made of solid and durable vulcanized rubber with glueing and stitching. The Belgian model 1996 boots uses the same layered out-sole, as on the failed German Bundeswehr "Model 2000" boots, the out-soles of which were composed of rubber and open-layer foamy polyurethane, which tend to deterioration and crushing after quite short time. Even the logo - the "Indian Head" is exactly the same as on the German "Model 2000" boots out-soles.

As we know, the shortcomings of this model became the reason for the Bundeswehr to opt out the "Model 2000" and adopt a new and very successful "model 2005/2007". The foamy layer of these boots out-sole was "hidden" inside, the general design and speed lacing system eyelets were improved as well.

Judging by the opinions, presented on the Belgian discussion forums, the users of the ABL latest model boots noticed the shortcomings of the new boots out-soles, and they use to write mostly negative reviews.

On the contrary, the "good old" Belgian boots are very much appreciated, because they have proven their superior performance and high quality of manufacturing, enabling many years of hard use.

Belgian army boots for wet and hot climate ("jungle" boots) are basically correspondent to the specific "Belgian" style. Similarly to the standard military boots of ABL (Armee Belge / Belgisch Leger), these "jungle" boots feature durable grain leather and the out-soles, which are glued and stitched. The boot's welt usually projects about a centimetre from the boot's top, providing thus the soldier's feet from potential injuries.

The Belgian ABL "jungle" boot's top is made of soft but durable black grain leather. In contrast to the "jungle" boots manufactured in the USA and Germany, top upper edge of the boots and additional oblique reinforcement strips on the both sides of the boots are made of grained leather as well. The fabric elements of the boot's top are made of black Cordura (nylon) - very lightweight and breathable material. The lacing system consists of eight pairs of simple round eyelets, made of rust-proof metal.

The black vulcanized rubber out-soles are of the classic "VIBRAM" tread pattern, quite common among many armies of NATO and neutral countries, from the UK and Italy to Austria and Switzerland.

The upper edge of the boots top features soft cushioning "collar" and made of soft "glove"- type leather inside. The number of lacing eyelets was increased by one extra pair, but, in contrast to the same type Dutch or Danish boots, the speed lacing system is not used. The lacing system elements, instead of a continuous leather strips is divided into 2 parts: 4 pairs of eyelets near the instep and five pairs of eyelets in the upper part. Between them there is a recessed curve, intended for convenience of the feet joint folding. The laces are of the circular cross section, as opposed to flat laces, used in conventional black ABL boots of Belgium.

Recently, the Belgian armed forces which take part in the UN and NATO operations are increasingly using the Airpower "desert" boots by "HAIX" company. This comfortable boots are lined with Gore-Tex, and the uppers are made of suede and composite textile materials. These boots are also widely used by the German Bundeswehr and a number of other armies.

This example clearly shows that globalization has also affected the armed forces: the standardization of uniforms and boots is combined with the decreasing of the national characteristics in the details of uniforms and equipment. It can be assumed that the gain of the process will lead to the situation when, for example the national uniforms of the Spaniards or Belgians will not differ from the uniforms of the Brits or Germans, with the exception of national symbolics like sleeve flags and military ranks.

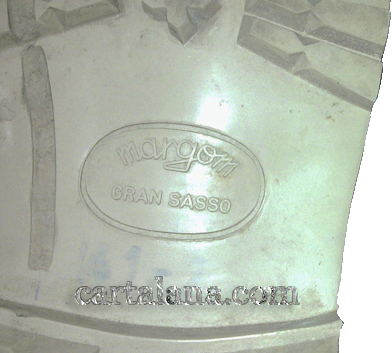

There are several types of Belgian military boots for hot and dry climate ("desert" boots). The oldest version is very lightweight, made of suede and canvas. The tread pattern of the out-sole is standard Italian "VIBRAM" design, and out-soles of these boots are manufactured by "MARGOM srl", an Italian company , located in Caronno Pertusella, a Lombardian town to the north-west of Milan.

In general, they are made similarly to the black "jungle ABL" boots, with the out-soles glued and stitched along the welt. The lacing system consists of eight pairs of round eyelets. The top edge of the boots and additional oblique reinforcement strips on the both sides of the boots are made of natural leather (suede) instead of nylon, which is used in German and American "desert" boots. In such a way, the main difference between these two types of boots ("jungle" and "desert") is the colour and type of leather used.

Later models of Belgian "desert" boots have undergone several changes. By their appearance, they began to resemble Danish"desert" boots (model R0001), manufactured by "LeBock" footwear company.

The out-soles of such boots are made of nitrile rubber and are actually of the DMS (Direct Moulded Sole) type. The tread pattern is a variant of the ones, used in the standard Dutch army models of the 1990s.

The upper edge of the boots top features soft cushioning "collar" and made of soft "glove"- type leather inside. The number of lacing eyelets was increased by one extra pair, but, in contrast to the same type Dutch or Danish boots, the speed lacing system is not used. The lacing system elements, instead of a continuous leather strips is divided into 2 parts: 4 pairs of eyelets near the instep and five pairs of eyelets in the upper part. Between them there is a recessed curve, intended for convenience of the feet joint folding. The laces are of the circular cross section, as opposed to flat laces, used in conventional black ABL boots of Belgium.

Recently, the Belgian armed forces which take part in the UN and NATO operations are increasingly using the Airpower "desert" boots by "HAIX" company. This comfortable boots are lined with Gore-Tex, and the uppers are made of suede and composite textile materials. These boots are also widely used by the German Bundeswehr and a number of other armies.

This example clearly shows that globalization has also affected the armed forces: the standardization of uniforms and boots is combined with the decreasing of the national characteristics in the details of uniforms and equipment. It can be assumed that the gain of the process will lead to the situation when, for example the national uniforms of the Spaniards or Belgians will not differ from the uniforms of the Brits or Germans, with the exception of national symbolics like sleeve flags and military ranks.

Exclusively for cartalana.com

We have much more interesting information on this site.

Click MENU to check it out!

∎ cartalana.com© 2009-2025 ∎ mailto: cartalana@cartalana.com